Why Does Battery Energy Density Matter?

Why Does Battery Energy Density Matter?

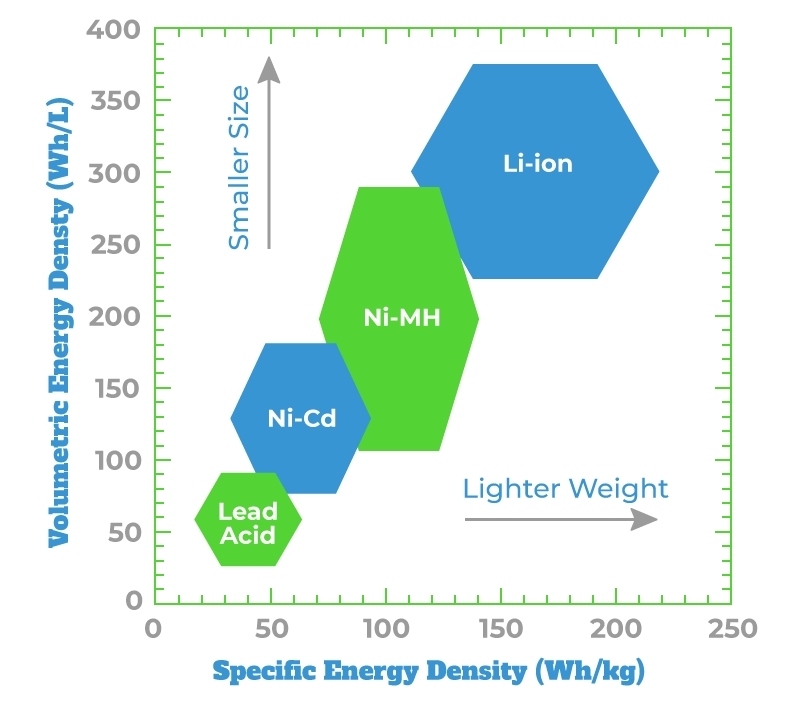

Battery energy density is the amount of energy a battery contains compared to its weight or size. We call this the specific energy density when comparing to weight and volumetric energy density when comparing size.

For example, we measure a battery’s energy in watt-hours (watts per hour, the equivalent of using one watt for one hour). We can then divide a battery’s watt hours (wh) by its kilograms (weight) or volume (liters).

Therefore, the length of time a battery can power a device compared to its weight or size equals the energy density.

Why Do You Need a Battery with High Energy Density?

To better understand lithium-ion batteries, you should understand why a high energy density is a desirable trait in a battery.

A battery with high energy density has a longer battery run time in relation to the battery size. Alternately, a battery with high energy density can deliver the same amount of energy, but in a smaller footprint compared to a battery with lower energy density. This greatly expands the possibilities for battery applications.

In factory or warehouse settings, forklift batteries can weigh thousands of pounds. A lightweight battery for forklifts offers some advantages in safety and handling.

If the energy density of a battery is too high, it could present a safety issue. When there’s more active material packed into a cell, it increases the risk of a thermal event.

Which Type of Rechargeable Battery Has the Highest Energy Density?

There are several different types of rechargeable batteries with a variety of energy densities reflective of their internal chemistry.

- Energy density of Lead acid battery ranges between 30-50 Wh/kg

- Energy density of Nickel-cadmium battery ranges between 45-80 Wh/kg

- Energy density of Nickel-metal hydride battery ranges between 60-120 Wh/kg

- Energy density of Lithium-ion battery ranges between 50-260 Wh/kg

Types of Lithium-Ion Batteries and their Energy Density

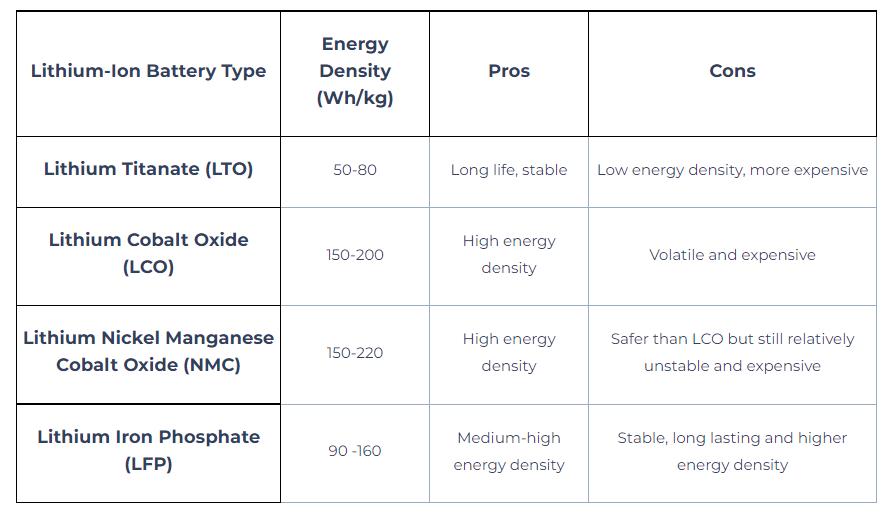

Lithium-ion batteries are often lumped together as a group of batteries that all contain lithium, but their chemical composition can vary widely and with differing performance as a result.

Most lithium-ion battery types share a similar design of a cathode with aluminium backing, a carbon or graphite anode with copper backing, a separator, and electrolyte made of lithium salt in an organic solvent.

Manufacturers have experimented with the materials used on the cathode & anode. They have also varied the composition of the electrolyte. These differences are what causes lithium-ion batteries to vary in their energy density levels.

Now we’ll review the most popular lithium-ion battery chemistries, along with their respective energy densities, use cases, benefits, and drawbacks.

Lithium titanate batteries offer extremely wide operating temperatures making them useful in aerospace applications.

Industry Titans: Lithium Titanate (LTO) Batteries

An LTO battery is one of the oldest types of lithium-ion batteries and has an energy density on the lower side as lithium-ion batteries go, around 50-80 Wh/kg.

In these batteries, lithium titanate is used in the anode in place of carbon, which allows electrons to enter and exit the anode faster than in other types of lithium-ion batteries.

This structure allows the LTO batteries to charge much faster and handle high currents safely, but the low energy density makes them poorly suited for material handling equipment.

They tend to be more expensive and are typically used for electric vehicles, car audio applications and mobile medical devices.

Laptops and other portable electronics commonly use LCO batteries.

High Energy, High Risk: Lithium Cobalt Oxide (LCO) Batteries

Lithium cobalt oxide batteries have a high energy density of 150-200 Wh/kg. Their cathode is made up of cobalt oxide with the typical carbon anode, with a layered structure that moves lithium-ions from anode to the cathode and back.

These types of batteries are popular for their high energy density and are typically used in cell phones, laptops, and most recently electric vehicles.

Cobalt is a very energy dense material, but it can be expensive. As demand increases for use in electric vehicles, it’s a rapidly depleting resource. In fact the world could face a cobalt supply shortage soon.

Cobalt is also highly volatile. Lithium-cobalt batteries can’t handle large currents because of the risk of overheating, which is a significant safety risk. LCO batteries have lower thermal stability, which means they are highly sensitive to higher operating temperatures and overcharging.

Electric cars often use NMC and NCA lithium batteries.

Performance with a Price: Lithium Nickel Manganese Cobalt Oxide (NMC) Batteries

Lithium nickel manganese cobalt oxide batteries also have a high energy density of 150-220 Wh/kg. They use cobalt in the cathode just like LCO batteries, but they also contain nickel and manganese to help add stability.

NMC batteries are used in most electric vehicles in production today but are also used for medical devices and e-bikes.

The secret to this battery’s success is its well-balanced chemistry; nickel is known to be energy-dense but unstable, just like cobalt, while manganese is more stable but also lower in energy density. The specific ratio of different elements varies by manufacturer, but the addition of nickel is typically intended to allow them to reduce the amount of expensive cobalt.

NMC batteries can handle larger charge currents and a greater range in temperature than LCO batteries. However, since the battery still contains cobalt, the cost is driven up due to market scarcity.

Affordable, Safe and Reliable: Lithium Iron Phosphate (LFP) Batteries

LFP batteries have a high energy density of 90-160 Wh/kg. While that is lower than some of the cobalt batteries, it is still among the highest of all the battery types.

LFP batteries use iron phosphate for the cathode and a graphite electrode combined with a metallic backing for the anode.

Lithium iron phosphate, or LiFePO4, is a naturally occurring mineral that is inexpensive, non-toxic and has good thermal stability with high energy density.

LFP batteries are ideal for heavy equipment and industrial environments because of their ability to withstand a lot of abuse and a wide range of temperatures. They have emerged as a new go-to option in forklifts and other heavy electric equipment that needs a high level of reliability and has historically relied on lead acid batteries.

All types of lithium-ion battery chemistries are unique. It is crucial to understand which lithium-ion chemistries are best suited for your application.

If you are searching for the best battery for your material handling equipment, a lithium iron phosphate battery is likely the best choice. All Basen LiFePO4 Packs are built exclusively with LFP cells because they offer the best balance between safety and performance.

.png)